SLAM-Professional 20+ years aluminum manufacturer with high quality and good price.

Wholesale SLAM Aluminum Alloy Manufacturers -

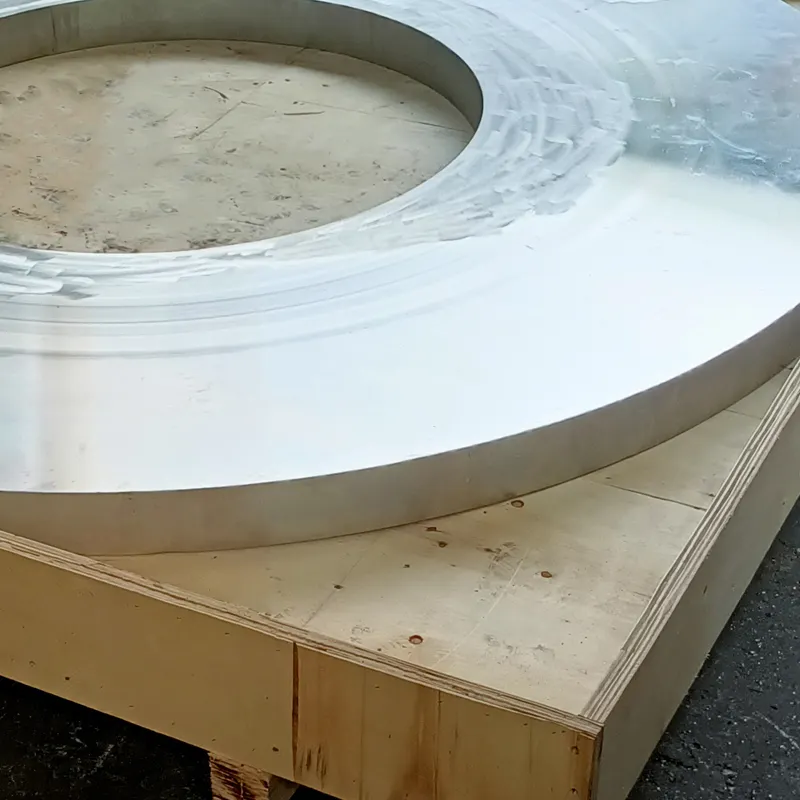

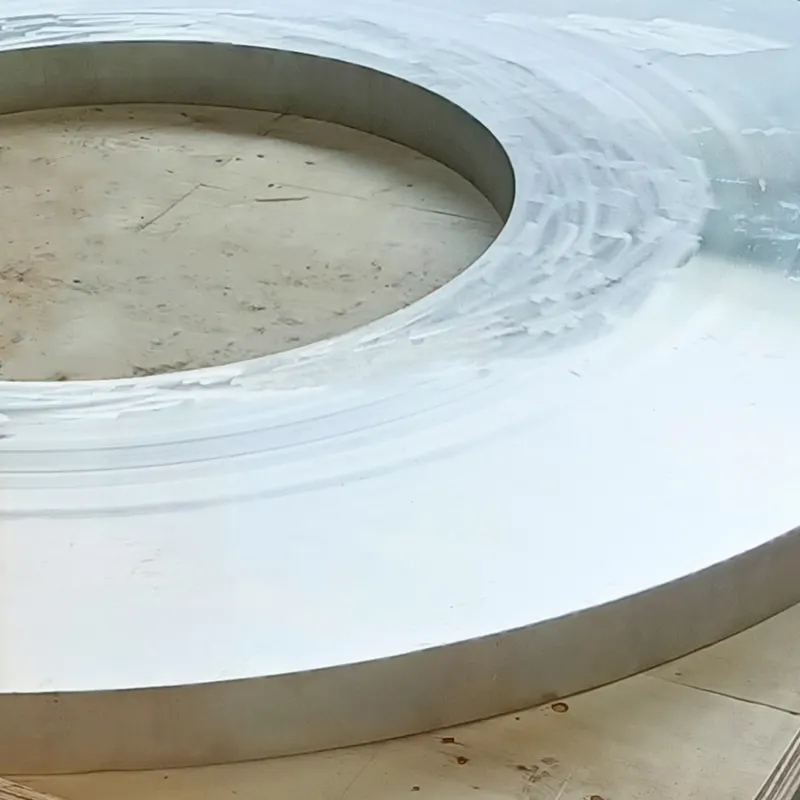

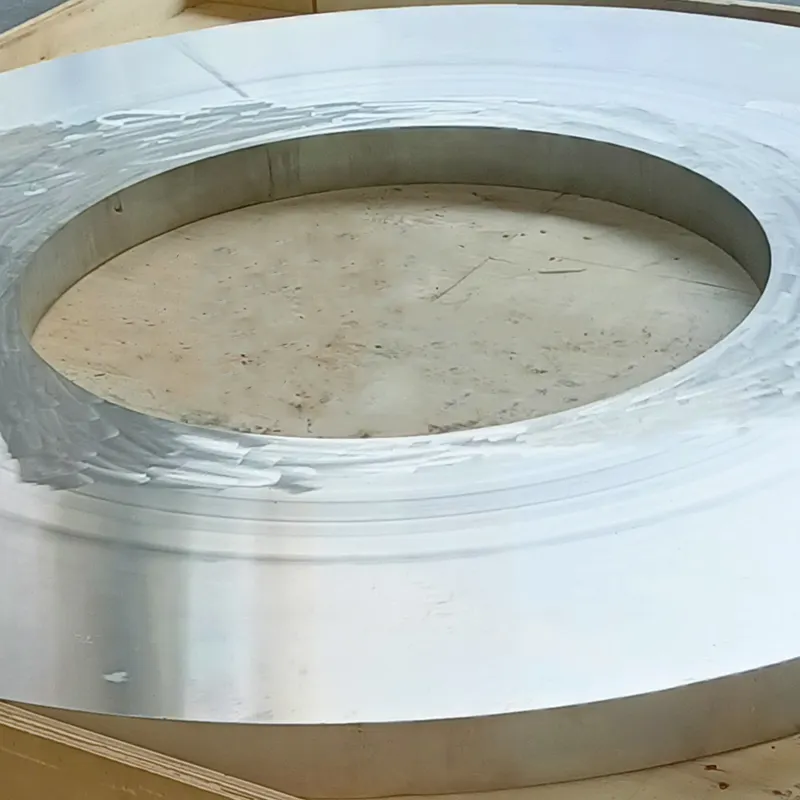

Product details of the aluminum alloy manufacturers

Product Description

During the production process, the design stage of SLAM aluminum alloy manufacturers is viewed as an important part. An appropriate programmed of quality control (qc) must be implemented in its production. Shanghai Lockheed Aviation Materials Co., Ltd. is backed by its strong technical strength and perfect customer service system.

Characteristics

7075 aluminum forged rings have several characteristics that make them ideal for a variety of applications:

1. High Strength: 7075 aluminum forged rings are known for their high strength-to-weight ratio, making them ideal for applications where strength is critical. The alloy can withstand high stress and extreme temperatures, without degrading or deforming.

2. Lightweight: 7075 aluminum forged rings are lightweight, making them ideal for applications where weight is a critical factor. The alloy is also easy to machine, making it ideal for applications where complex shapes and designs are required.

3. Corrosion Resistance: 7075 aluminum forged rings are highly resistant to corrosion, making them an ideal choice for applications where exposure to harsh environments and chemicals is unavoidable.

4. Good Weldability: 7075 aluminum forged rings are easy to weld, making them ideal for applications where welding is an essential process.

5. Heat Treatment: 7075 aluminum forged rings can be heat treated to improve their strength, hardness, and toughness, making them ideal for applications where these properties are critical.

Chemical Composition

Silicon Si: 0.40

Iron Fe: 0.50

Copper Cu: 1.2-2.0

Manganese Mn: 0.30

Magnesium Mg: 2.1-2.9

Chromium Cr: 0.18-0.28

Zinc Zn: 5.1-6.1

Titanium Ti: 0.20

Aluminum Al: Surplus

Other: Individual: 0.05 Total: 0.15

Mechanical Properties

The mechanical properties of 7075 aluminum alloy forging grade are as follows:

Tensile strength: 83,000 psi (572 MPa)

Yield strength: 73,000 psi (503 MPa)

Elongation: 11%

Hardness: Brinell 150

Applications

7075 aluminum forged rings are extensively used in aerospace industries, military, and sports equipment applications, where strength and weight are critical factors. These forged rings are commonly used in the following applications:

1. Aircraft structures and components, such as wings, fuselage, and landing gear.

2. Military applications, such as firearms, armored vehicles, and missile launchers.

3. Sporting equipment, such as bicycle frames, ski poles, and climbing gear.

4. High-performance automotive parts, such as engine blocks, suspension components, and driveshafts.

Conclusion

7075 aluminum forged rings are an ideal choice for applications where strength, weight, and corrosion resistance are critical factors. The alloy's high strength-to-weight ratio, good weldability, and heat treatment capabilities make it suitable for a variety of applications, including aerospace, military, and sports equipment. While the alloy is expensive, its superior properties and outstanding performance make it an excellent investment for high-stress applications.

Company Feature

• Having experienced years of arduous development and innovation, SLAM is now an enterprise with leading production technology in the industry.

• SLAM enjoys developed telecommunication and traffic convenience. The geographic location is superior and the natural conditions are good.

• SLAM gathers a group of staff with dreams, abilities, and passion. With the common goal, we cooperate with each other and make effort together to continuously develop our company sustainably.

• SLAM takes constant innovation and improvement on the service model and strives to provide efficient and considerate services for customers.

If you are interested in SLAM's please leave your contact information. We will get back to you as soon as possible.