SLAM-Professional 20+ years aluminum manufacturer with high quality and good price.

The Advantages Of Aluminum Forging Discs In Industrial Applications

Welcome to our article on "The Advantages of Aluminum Forging Discs in Industrial Applications." Aluminum forging discs have become an integral part of various industries due to their numerous benefits and applications. In this article, we will delve into the advantages of using aluminum forging discs in industrial settings and how they can enhance efficiency and performance. Whether you are looking to improve your manufacturing processes or seeking to understand the benefits of aluminum forging discs, this article will provide valuable insights that you won't want to miss. Keep reading to explore the endless possibilities of aluminum forging discs in industrial applications.

- The Properties of Aluminum Forging Discs

Aluminum forging discs are an essential component in many industrial applications due to their unique properties and benefits. As a leading manufacturer of aluminum forging discs, SLAM understands the importance of utilizing this material in industrial processes. In this article, we will explore the specific properties of aluminum forging discs and their advantages in various industrial applications.

Aluminum forging discs are known for their exceptional strength and durability. This makes them an ideal choice for applications that require high-performance and reliability. SLAM’s aluminum forging discs are carefully engineered to meet the highest industry standards, ensuring that they can withstand extreme conditions and heavy loads. This makes them suitable for use in industries such as aerospace, automotive, and oil and gas.

In addition to their strength, aluminum forging discs have excellent corrosion resistance. This is a crucial property in industrial applications, where components are exposed to harsh environments and chemicals. SLAM’s aluminum forging discs are designed to withstand corrosion, making them an ideal choice for applications that require long-term durability and reliability.

Another key property of aluminum forging discs is their lightweight nature. Despite their impressive strength and durability, aluminum forging discs are significantly lighter than other materials such as steel. This makes them a popular choice in industries where weight reduction is a priority, such as automotive and aerospace. The lightweight nature of aluminum forging discs also contributes to easier handling and installation, reducing labor costs and time.

Furthermore, aluminum forging discs possess excellent thermal conductivity, making them an ideal choice for applications that require efficient heat transfer. This property allows for the effective dissipation of heat, which is crucial in industries such as heat exchangers and cooling systems. SLAM’s aluminum forging discs are designed to optimize thermal conductivity, ensuring efficient operation in critical industrial processes.

Another advantage of aluminum forging discs is their ease of machinability. SLAM’s aluminum forging discs are designed for precision machining, allowing for the creation of complex shapes and designs. This versatility makes them suitable for a wide range of industrial applications, from simple components to intricate parts.

In conclusion, the properties of aluminum forging discs make them an essential component in industrial applications. SLAM’s superior quality aluminum forging discs are designed to meet the demands of various industries, offering exceptional strength, corrosion resistance, lightweight nature, thermal conductivity, and ease of machinability. By utilizing aluminum forging discs from SLAM, industrial processes can benefit from enhanced performance, reliability, and efficiency. Whether it is for aerospace, automotive, or oil and gas applications, aluminum forging discs play a crucial role in driving industrial innovation and advancement.

- The Durability and Strength of Aluminum Forging Discs

Aluminum forging discs are an essential component in various industrial applications, providing durability and strength in a wide range of processes. At SLAM, we understand the importance of utilizing high-quality materials in industrial settings, which is why we offer a superior selection of aluminum forging discs for our customers.

One of the key advantages of aluminum forging discs is their unmatched durability. Through the forging process, aluminum discs are shaped and compressed to create a dense and strong structure that can withstand high levels of pressure and impact. This durability makes aluminum forging discs an ideal choice for applications that involve heavy machinery, intense heat, or corrosive environments.

In addition to their durability, aluminum forging discs also offer exceptional strength. The forging process aligns the aluminum's grain structure, resulting in a material that is significantly stronger than cast or machined aluminum. This high strength-to-weight ratio makes aluminum forging discs a lightweight yet robust option for industrial uses, allowing for improved efficiency and performance in a variety of operations.

Another key advantage of aluminum forging discs is their resistance to fatigue and wear. The forging process creates a fine-grained and homogeneous microstructure within the aluminum, which enhances its resistance to fatigue failure and wear over time. This means that aluminum forging discs are able to maintain their structural integrity and performance, even after prolonged use in demanding industrial environments.

Furthermore, aluminum forging discs offer excellent thermal and electrical conductivity, making them a versatile choice for applications that require efficient heat transfer or electrical conduction. This conductivity can be particularly beneficial in industries such as automotive manufacturing, aerospace, and electronics, where the performance and reliability of materials are crucial.

At SLAM, we are committed to providing our customers with the highest quality aluminum forging discs that offer exceptional durability and strength. Our extensive experience and expertise in the forging industry allow us to produce aluminum discs that meet the stringent requirements of various industrial applications. Whether it's for use in heavy-duty machinery or precision engineering, our aluminum forging discs deliver the reliability and performance that our customers expect.

In conclusion, the durability and strength of aluminum forging discs make them a superior choice for a wide range of industrial applications. Their ability to withstand high levels of pressure and impact, coupled with their resistance to fatigue and wear, make them an invaluable component in demanding industrial settings. At SLAM, we take pride in offering top-quality aluminum forging discs that meet the diverse needs of our customers, providing them with a reliable and efficient solution for their industrial requirements.

- The Versatility and Cost-Effectiveness of Aluminum Forging Discs

Aluminum forging discs are an essential component in various industrial applications, thanks to their versatility and cost-effectiveness. In this article, we will delve into the numerous advantages that aluminum forging discs offer in industrial settings, as well as the reasons why they are preferred over other materials. As a leading manufacturer in the industry, SLAM has perfected the art of producing high-quality aluminum forging discs that meet the diverse needs of our customers.

One of the key reasons why aluminum forging discs are highly sought after in industrial applications is their versatility. These discs are used in a wide range of industries, including automotive, aerospace, construction, and manufacturing. Their ability to withstand high temperatures and pressures makes them ideal for applications that require strength and durability. Whether it's for creating parts for automotive engines or components for aircraft, aluminum forging discs are the go-to choice for many industrial engineers and manufacturers.

In addition to their versatility, aluminum forging discs are also known for their cost-effectiveness. Unlike other materials, aluminum is abundant and easily accessible, making it a more affordable option for industrial purposes. The forging process further enhances the material's strength and durability, ensuring that it can withstand the rigors of industrial use without incurring high production costs. This cost-effectiveness is especially beneficial for companies looking to reduce overheads and maximize profits without compromising on quality.

At SLAM, we understand the importance of producing aluminum forging discs that not only meet industry standards but also exceed customer expectations. Our state-of-the-art manufacturing facilities and skilled workforce enable us to create aluminum forging discs that are not only versatile and cost-effective but also superior in quality. We take pride in our ability to deliver products that cater to a wide range of industrial applications, providing our customers with the peace of mind that comes with using reliable and durable components.

Furthermore, our commitment to sustainability sets us apart in the industry. Aluminum is a highly recyclable material, and our forging process minimizes waste while maximizing the material's potential. This not only reduces the environmental impact of our operations but also allows us to offer eco-friendly solutions to our clients. By choosing SLAM's aluminum forging discs, businesses can align with their sustainability goals while reaping the benefits of a reliable and cost-effective material.

In conclusion, the advantages of aluminum forging discs in industrial applications are vast and undeniable. From their versatility to their cost-effectiveness and sustainability, these components offer a range of benefits that make them an essential part of various industrial processes. As a leading manufacturer in the industry, SLAM is dedicated to providing high-quality aluminum forging discs that cater to the diverse needs of our clients. With our commitment to excellence and sustainability, we continue to set the standard for aluminum forging discs in the industrial sector.

- The Importance of Quality Control in Aluminum Forging Discs

Aluminum forging discs play a vital role in various industrial applications due to their exceptional strength, durability, and versatility. However, in order to ensure the highest level of performance and safety, quality control in the production of these discs is of utmost importance. This article will delve into the advantages of aluminum forging discs in industrial applications and emphasize the significance of quality control to maintain their superior quality.

Aluminum forging discs are widely used in industries such as aerospace, automotive, and manufacturing for their ability to withstand high temperatures, heavy loads, and corrosion resistance. These discs are often utilized in critical components where precision and reliability are essential. One of the key advantages of aluminum forging discs is their superior mechanical properties, making them an ideal choice for demanding industrial environments.

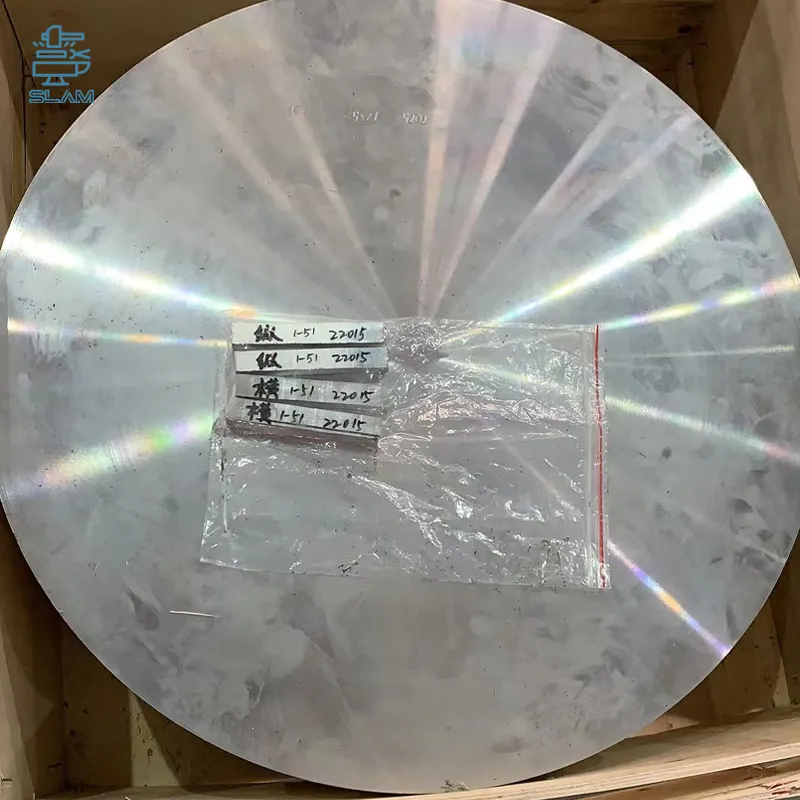

At SLAM, we understand the importance of quality control in the production of aluminum forging discs. Our manufacturing process involves stringent quality checks at every stage to ensure that the discs meet the highest standards of performance and reliability. From the selection of top-grade aluminum alloys to the forging and heat treatment processes, we prioritize quality control to deliver superior products to our customers.

Quality control in aluminum forging discs begins with the selection of raw materials. At SLAM, we carefully source high-quality aluminum alloys with the desired mechanical properties to ensure that our forging discs meet and exceed the performance requirements of our industrial customers. These alloys undergo rigorous testing to verify their integrity and suitability for forging processes, setting the foundation for the production of premium-quality discs.

The forging process is another critical aspect where quality control plays a pivotal role. At SLAM, we leverage advanced forging techniques and state-of-the-art equipment to achieve precise dimensions, excellent surface finish, and optimal mechanical properties in our aluminum discs. Our skilled craftsmen and quality control experts monitor the forging process closely to maintain tight tolerances and eliminate any defects that may compromise the integrity of the discs.

Furthermore, heat treatment is an essential step in the production of aluminum forging discs to enhance their strength, toughness, and resistance to fatigue. Quality control measures are implemented to ensure that the heat treatment process is carried out with precision and consistency, resulting in discs with uniform microstructures and improved mechanical properties. This meticulous approach to quality control sets SLAM apart as a trusted supplier of high-performance aluminum forging discs.

In conclusion, the advantages of aluminum forging discs in industrial applications are indisputable, thanks to their exceptional strength and durability. However, to maximize the benefits of these discs, stringent quality control in their production is essential. At SLAM, we are committed to upholding the highest standards of quality control to deliver aluminum forging discs that excel in performance, reliability, and longevity. With our dedication to quality and precision, customers can trust SLAM as their preferred source for premium aluminum forging discs in their industrial operations.

- The Diverse Industrial Applications of Aluminum Forging Discs

Aluminum forging discs are a versatile and essential component in a wide range of industrial applications. From aerospace to automotive, and from defense to construction, the utilization of aluminum forging discs has become increasingly prevalent due to their numerous advantages. In this article, we will explore the diverse industrial applications of aluminum forging discs and delve into the benefits they offer across various sectors.

Aerospace is one of the primary industries that heavily rely on aluminum forging discs. The lightweight and high strength-to-weight ratio of aluminum make it an ideal material for aircraft components. Aluminum forging discs are used in the production of critical parts such as landing gear components, wing fittings, and structural components. The superior strength and durability of forged aluminum discs make them essential for ensuring the safety and reliability of aircraft.

In the automotive industry, aluminum forging discs play a crucial role in the manufacturing of engine parts, transmission components, and structural elements. The use of aluminum forging discs in automobiles offers several benefits including reduced weight, improved fuel efficiency, and enhanced overall performance. Additionally, the excellent heat dissipation properties of aluminum make it an ideal material for brake components, further driving the demand for aluminum forging discs in the automotive sector.

Defense applications also benefit from the use of aluminum forging discs due to their exceptional strength and resistance to corrosion. The lightweight nature of aluminum forging discs is particularly advantageous in the defense industry, where the development of advanced weaponry and military vehicles requires materials that can withstand extreme conditions while remaining agile and maneuverable. Whether it's in the manufacturing of armored vehicles, munitions, or aircraft, aluminum forging discs are an integral part of the defense supply chain.

In the construction industry, aluminum forging discs are utilized in the fabrication of structural components, scaffolding, and architectural elements. The malleability of aluminum allows for the creation of intricate and complex designs, while its superior strength ensures the integrity of the structures it supports. Additionally, the corrosion-resistant properties of aluminum forging discs make them an ideal choice for construction projects in diverse environmental conditions.

The advantages of aluminum forging discs in industrial applications are further amplified by their cost-effectiveness and sustainability. The production process of aluminum forging discs consumes less energy compared to other materials, resulting in lower manufacturing costs and reduced environmental impact. Furthermore, the recyclability of aluminum makes it a sustainable choice for industries looking to minimize their carbon footprint and contribute to environmental conservation.

At SLAM, we specialize in the production of high-quality aluminum forging discs that meet the stringent requirements of diverse industrial applications. Our state-of-the-art facilities and advanced forging techniques allow us to deliver precision-engineered forging discs that excel in performance, reliability, and durability. With a commitment to excellence and innovation, SLAM continues to be at the forefront of providing industry-leading aluminum forging discs for a wide range of applications.

In conclusion, the diverse industrial applications of aluminum forging discs underscore their unparalleled versatility and reliability in various sectors. From aerospace and automotive to defense and construction, the unique properties of aluminum forging discs continue to drive their widespread adoption and contribute to advancements in engineering and manufacturing. As industries continue to evolve, the demand for high-performance aluminum forging discs will remain integral to their success and progress.

Conclusion

In conclusion, aluminum forging discs offer numerous advantages for industrial applications. From their exceptional strength and durability to their resistance to corrosion and versatility, these discs are a valuable asset in a wide range of industries. Additionally, their lightweight nature and ability to withstand high temperatures make them an ideal choice for various manufacturing processes. With their ability to be customized and their cost-effectiveness, aluminum forging discs are a top choice for many industrial applications. Overall, the numerous benefits of aluminum forging discs make them a vital component in modern industrial processes, and their usage is likely to continue growing in the years to come.