SLAM-Professional 20+ years aluminum manufacturer with high quality and good price.

Aluminum Alloy Die Casting Manufacturers SLAM,

Product details of the aluminum alloy die casting manufacturers

Product Overview

SLAM aluminum alloy die casting manufacturers is designed in accordance with the basic production standard. Product quality is guaranteed because strict quality control processes effectively eliminate defects. Shanghai Lockheed Aviation Materials Co., Ltd. has been specialized in production of aluminum alloy die casting manufacturers for many years.

Product Introduction

The details of aluminum alloy die casting manufacturers are shown for you at below.

Characteristics

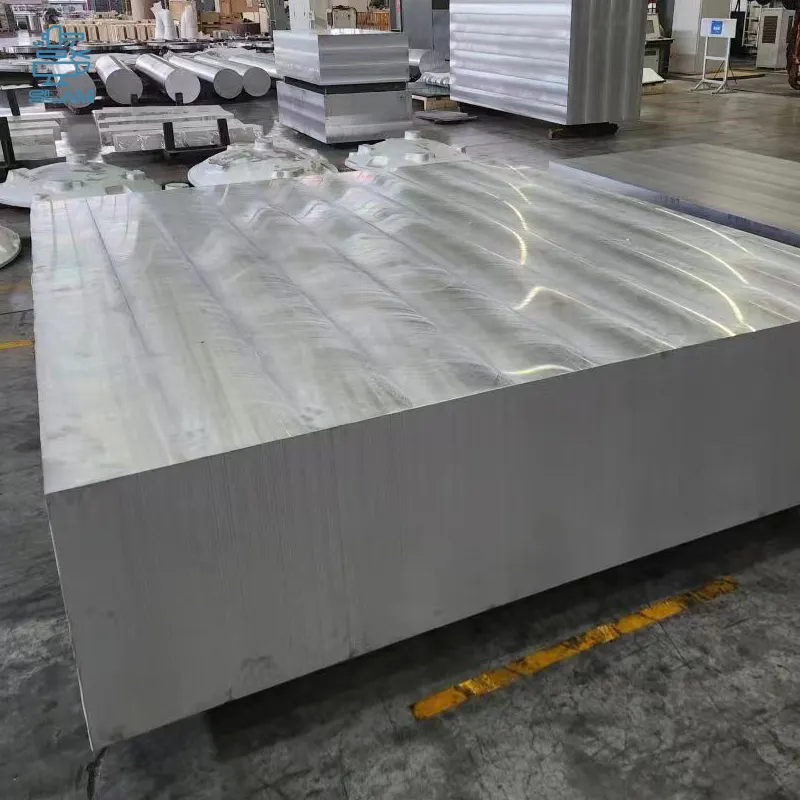

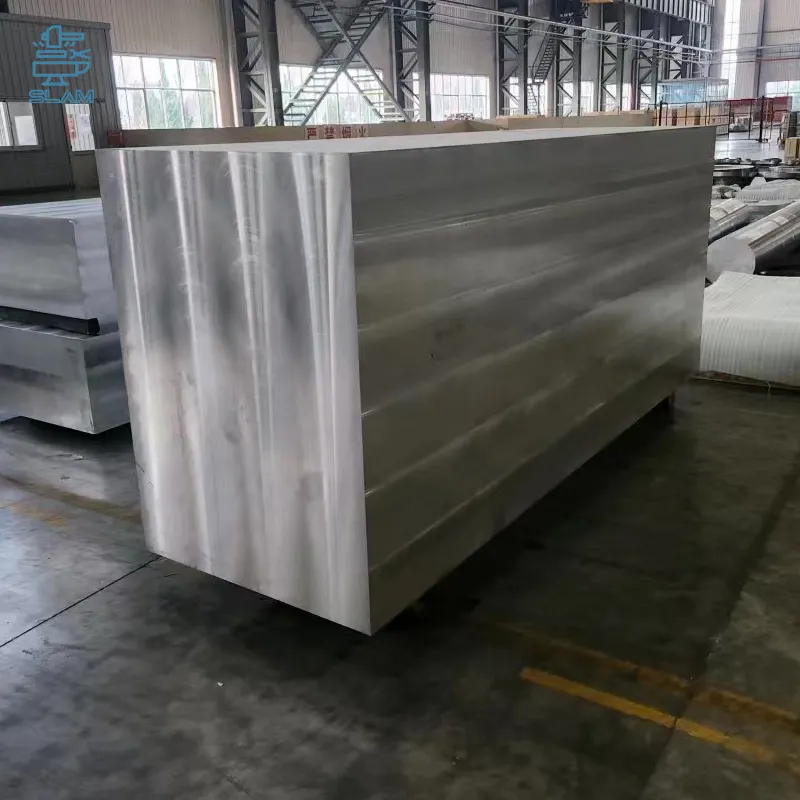

The 7075 T6/T651 aluminum forging block comes with the following properties:

1. High strength

2. Excellent fatigue resistance

3. Good toughness

4. Corrosion resistance

5. Machinability

6. Weldability

Chemical Composition

The chemical composition of 7075 T6/T651 aluminum forging block is as follows-:

Zinc: 5.6% to 6.1%

Magnesium: 2.1% to 2.9%

Copper: 1.2% to 2.0%

Chromium: 0.18% to 0.28%

Iron: 0.5% max

Silicon: 0.4% max

Titanium: 0.2% max

Manganese: 0.3% max

Other: 0.15% max each, 0.05% max total

Mechanical Properties

The 7075 T6/T651 aluminum forging block has excellent mechanical properties, which are as follows-:

Ultimate Tensile Strength: 83 ksi (572 MPa)

Yield Strength: 73 ksi (503 MPa)

Elongation: 11%

Hardness: 150 Brinell

Applications

The 7075 T6/T651 aluminum forging block is widely used in various industries due to its excellent mechanical and chemical properties. Some of its key applications include:

1. Aerospace industry-: The alloy is used to manufacture components in aircraft, such as wings, fuselages, and landing gear.

2. Military industry-: The 7075 T6/T651 alloy is used in the production of military vehicles, armaments, and ammunition.

3. Automotive industry-: The alloy is used to manufacture car components, such as wheels, suspension components, and chassis parts.

4. Sports equipment-: The alloy is used to manufacture bicycles, climbing equipment, and other sports equipment, thanks to its excellent strength and light weight.

5. Medical equipment-: The alloy is used to manufacture surgical instruments, prosthetic limbs, and other medical equipment that requires high strength and low weight.

Conclusion

In conclusion, the 7075 T6/T651 aluminum forging block is an exceptional aluminum alloy that is highly sought after due to its excellent mechanical and chemical properties. This material is known for its strength, toughness, fatigue resistance, and corrosion resistance, making it suitable for use in various industries and applications. Its chemical composition and mechanical properties make it a valuable material in industries such as military, aerospace, automotive, and medical.

Company Information

Shanghai Lockheed Aviation Materials Co., Ltd. (SLAM) is a comprehensive enterprise. We are engaged in scientific research, production, processing, marketing and service. are the major products. SLAM keeps carrying forward the enterprise spirit of 'morality, pragmatism, and innovation'. We devote ourselves to seek practical innovation in business management. We adopt the advanced management mode for modern enterprise and strive to become a leading company in the industry. SLAM takes talents cultivation seriously. This is why we establish a loyal and efficient talents team comes out. The team members have professional skills. With rich manufacturing experience and strong production capability, SLAM is able to provide professional solutions according to customers' actual needs.

We have been providing high quality aluminum alloy die casting manufacturers for a long time. We look forward to working with you.