SLAM-Professional 20+ years aluminum manufacturer with high quality and good price.

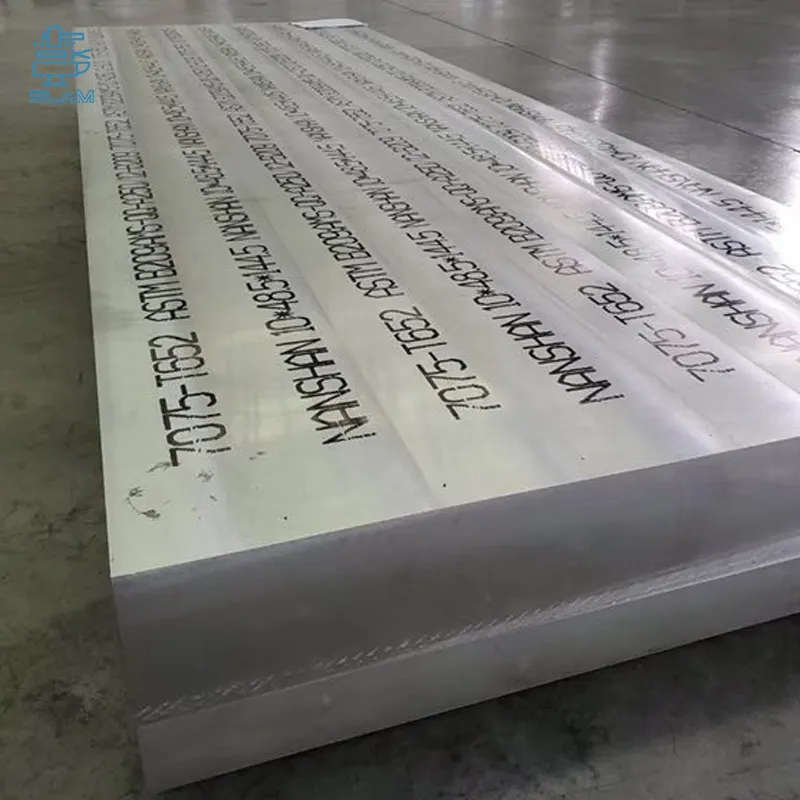

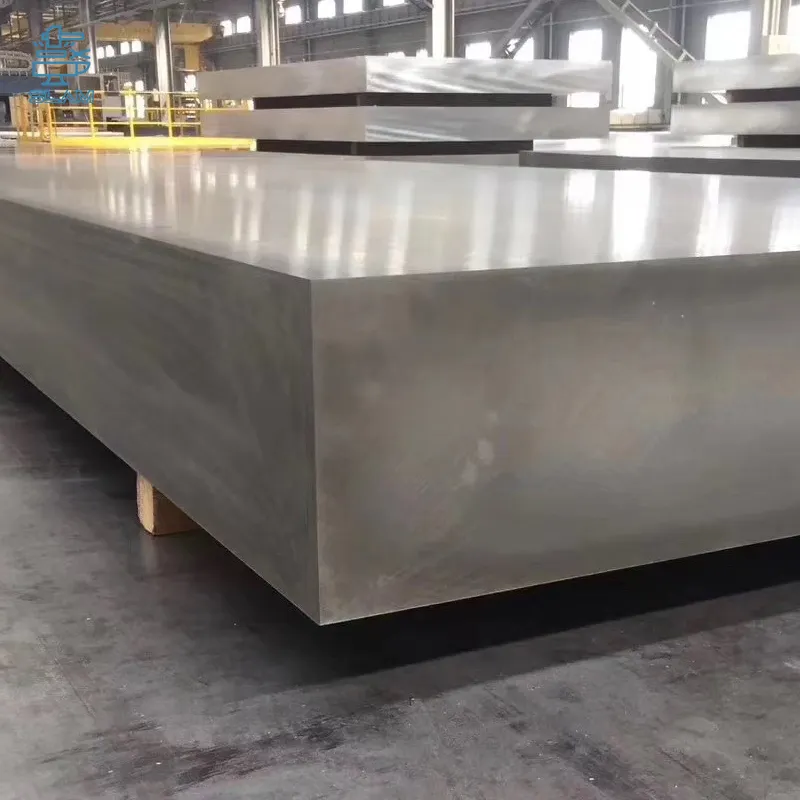

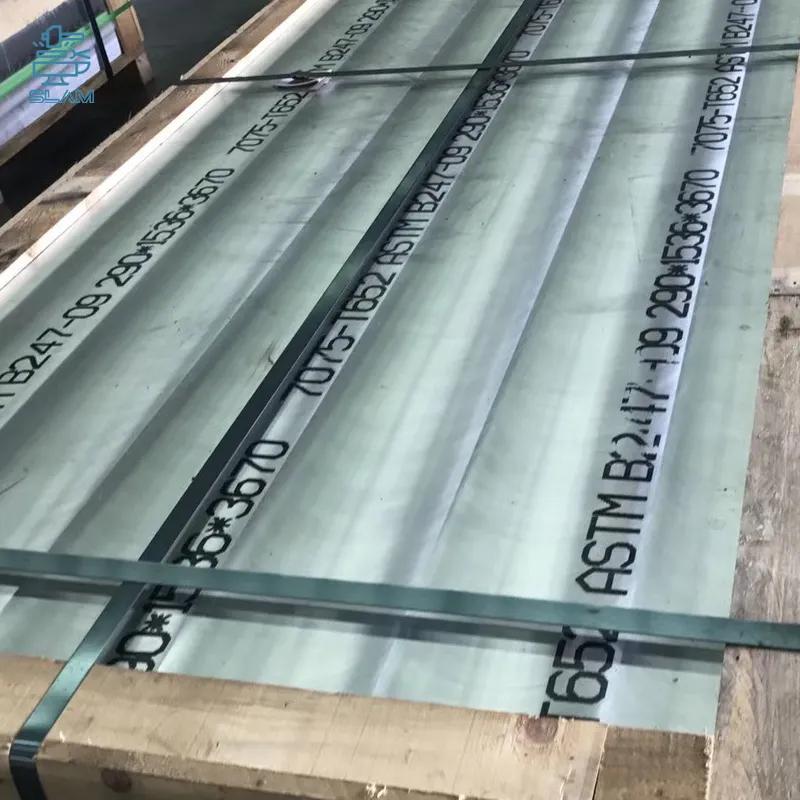

Bulk Cast Aluminum Plate Cast Aluminum Plate Company

Product details of the cast aluminum plate

Quick Overview

The quality and safety of all the materials used for SLAM cast aluminum plate are extremely important. It adopts high-tech for product performance improvement. cast aluminum plate developed and produced by SLAM is widely applied to many industries and fields. It can fully meet the diversified needs of customers. To meet the requirements of our customers all over the world, we have equipped cast aluminum plate with advanced production lines and experienced technicians.

Product Description

Compared with similar products, SLAM's cast aluminum plate has the following advantages.

Characteristics

7075 T652 aluminum forged plate has many features that make it a popular choice in many industries. Below are some of its features:

1. High strength: The combination of zinc, magnesium, and copper creates a strong and durable alloy.

2. Good formability: Despite its high strength, 7075 T652 aluminum forged plate has good formability, which allows it to be easily shaped into different forms without cracking or breaking.

3. Excellent machinability: This aluminum alloy has good machinability, which allows it to be easily machined into different shapes and sizes.

4. Resistance to stress corrosion cracking: The high resistance to stress corrosion cracking makes 7075 T652 aluminum forged plate particularly suitable for use in harsh environments.

Chemical Composition

7075 T652 aluminum forged plate is composed of the following elements:

Aluminum (Al): 90.7%

Zinc (Zn): 5.6%

Magnesium (Mg): 2.5%

Copper (Cu): 1.6%

Chromium (Cr): 0.2%

Other elements: 0.4%

The high content of zinc and magnesium makes 7075 T652 aluminum forged plate have excellent mechanical properties, such as high strength, good fatigue resistance, and stress corrosion cracking resistance.

Mechanical Properties

Mechanical properties are critical factors in determining whether an aluminum alloy is suitable for various applications. The mechanical properties of 7075 T652 aluminum forged plate are:

Tensile strength: 572 MPa

Yield strength: 503 MPa

Elongation: 11%

HB hardness: 150

The high tensile and yield strength make 7075 T652 aluminum forged plate ideal for applications where strength is essential, such as in the construction of aircraft parts, missiles, and spacecrafts.

Applications

The combination of excellent mechanical properties and unique features make 7075 T652 aluminum forged plate widely used in various industries. Below are some of its applications:

1. Aerospace industry: 7075 T652 aluminum forged plate is used in the construction of aircraft, missiles, and spacecraft parts due to its strength and durability.

2. Military industry: This aluminum alloy is used in the design and construction of military equipment, including firearms, tanks, and armored vehicles.

3. Transportation industry: It is used in the construction of various vehicles, including cars, trains, and ships.

4. Sports equipment: This alloy is used in the manufacture of sports equipment such as bikes, skis, and snowboards.

Conclusion

In conclusion, 7075 T652 aluminum forged plate is a high-strength aluminum alloy with excellent mechanical properties and unique features that make it popular in various industries. Its chemical composition, mechanical properties, features, and applications have been discussed in this article. As a result, 7075 T652 aluminum forged plate represents a promising future in materials science and technology.

Company Introduction

In China's cast aluminum plate industry, SLAM is famous for the products of uniqueness and innovativeness. We have brought together a team of experienced designers. With their years of experience in the field of cast aluminum plate, they are able to help the company design products with functionality, performance, as well as visual appeal. We wish to take hand in hand with customers to make contribution for cast aluminum plate industry. Call!

Welcome to discuss business cooperation with us!