SLAM-Professional 20+ years aluminum manufacturer with high quality and good price.

Cost-effective Aluminum Alloy Die Casting Manufacturers Manufacturer for Aerospace Industry

Product details of the aluminum alloy die casting manufacturers

Quick Overview

With the assistance of the professionals, the production of SLAM aluminum alloy die casting manufacturers is highly efficient and accurate. It attracts users' attention with its easy-to-use performance. From raw material procurement to product development and manufacturing, each link is strictly controlled in Shanghai Lockheed Aviation Materials Co., Ltd..

Product Information

In the production process of aluminum alloy die casting manufacturers, we carefully polish the details, so as to strive for perfect quality.

Characteristics

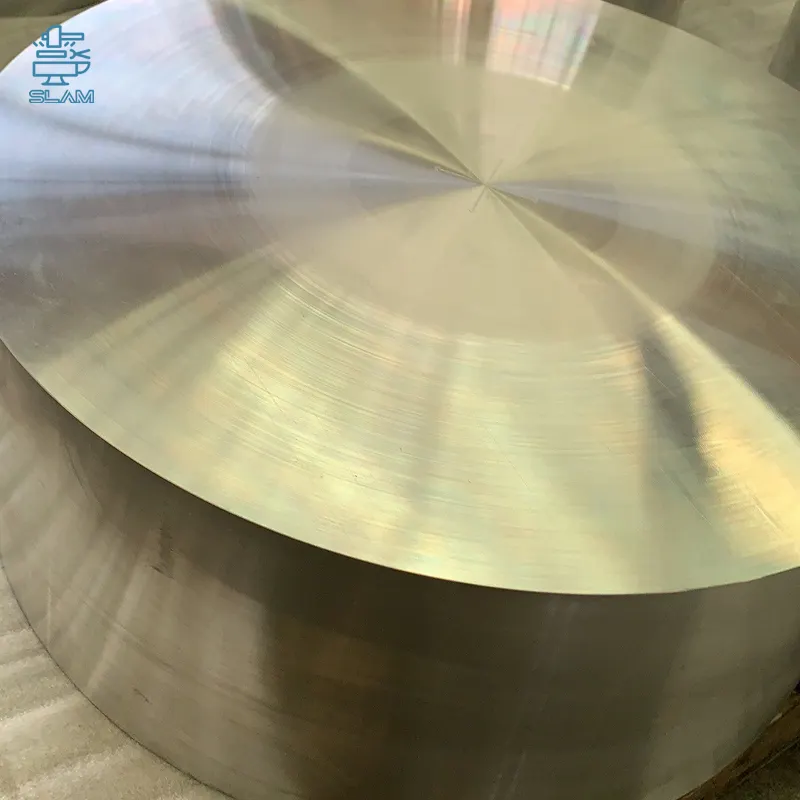

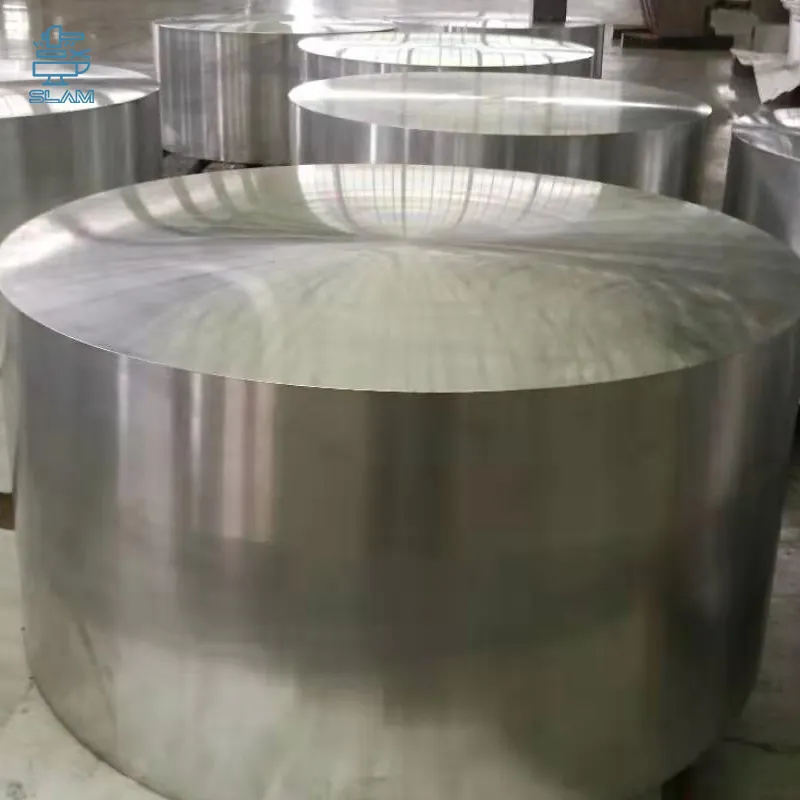

7075 aluminum forgings are manufactured through the process of hot forging, which involves heating the metal to a temperature of approximately 450-500°C and then applying pressure to shape it into the desired form. This process gives the material its high strength and excellent mechanical properties, as well as its ability to resist fatigue and corrosion.

The forgings are then heat-treated to further enhance their properties, typically undergoing a solution heat treatment at 465°C for several hours followed by quenching in water. This treatment improves the material's strength and toughness, making it suitable for use in a wide range of applications.

Chemical Composition

7075 aluminum is primarily composed of aluminum, with small amounts of copper, zinc, magnesium, and chromium. The exact chemical composition of 7075 aluminum varies depending on the specific alloy and manufacturing process used, but typical values are as follows:

Aluminum: 90.5%

Copper: 1.6%

Zinc: 5.6%

Magnesium: 2.5%

Chromium: 0.23%

Mechanical Properties

7075 aluminum forgings have excellent mechanical properties, including high strength, toughness, and fatigue resistance. The tensile strength of this material typically ranges from 540-570 MPa, with a yield strength of 470-505 MPa and an elongation of 6-7%. The material also exhibits good toughness, with a Charpy impact strength of 47-48 J/cm^2.

In addition, 7075 aluminum has low density, which gives it an exceptional strength-to-weight ratio. This makes it an ideal material for aircraft and spacecraft components, where weight must be minimized without sacrificing strength or durability.

Applications

7075 aluminum forgings are commonly used in aerospace and defense applications, where high strength-to-weight ratio is essential. These forgings are used to produce round disks or discs that are used in various aircraft structures, such as engine mounts, wing spars, and landing gear components. The material is also used in military vehicles and weapons, where its strength and durability make it ideal for use in armor, missile parts, and other critical components.

Conclusion

7075 aluminum forgings are an essential material in the aerospace and defense industries. They offer exceptional strength, toughness, and resistance to fatigue and corrosion, making them ideal for use in aircraft and spacecraft components, military vehicles, and weapons. With its unique combination of mechanical properties and excellent production processes, 7075 aluminum is an essential material in modern engineering and technology.

Company Introduction

Shanghai Lockheed Aviation Materials Co., Ltd. is a modern company mainly engaged in research and development, production and sales. Our main product is SLAM attaches great importance to quality and credit during the business management. We follow the enterprise spirit to be optimistic and active, positive and aspirant, innovative and developing. In order to provide quality products, we continuously improve our core competitiveness and implement the development strategy of scale-business. It is our honor to bring a relaxing buying experience to customers. With a focus on talents cultivation, our company has established an innovative talent team. The team members have innovative thinking and management capabilities. With rich manufacturing experience and strong production capability, SLAM is able to provide professional solutions according to customers' actual needs.

Our products are of guaranteed quality and tight package. Welcome customers with needs to contact us!