SLAM-Professional 20+ years aluminum manufacturer with high quality and good price.

Reliable Aluminum Alloy Forgings Price List

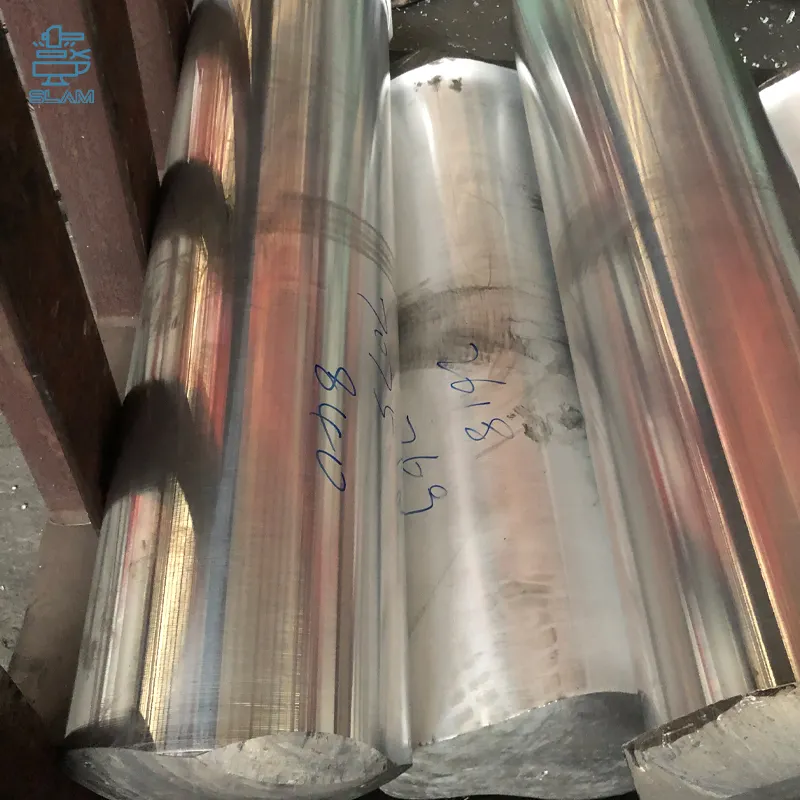

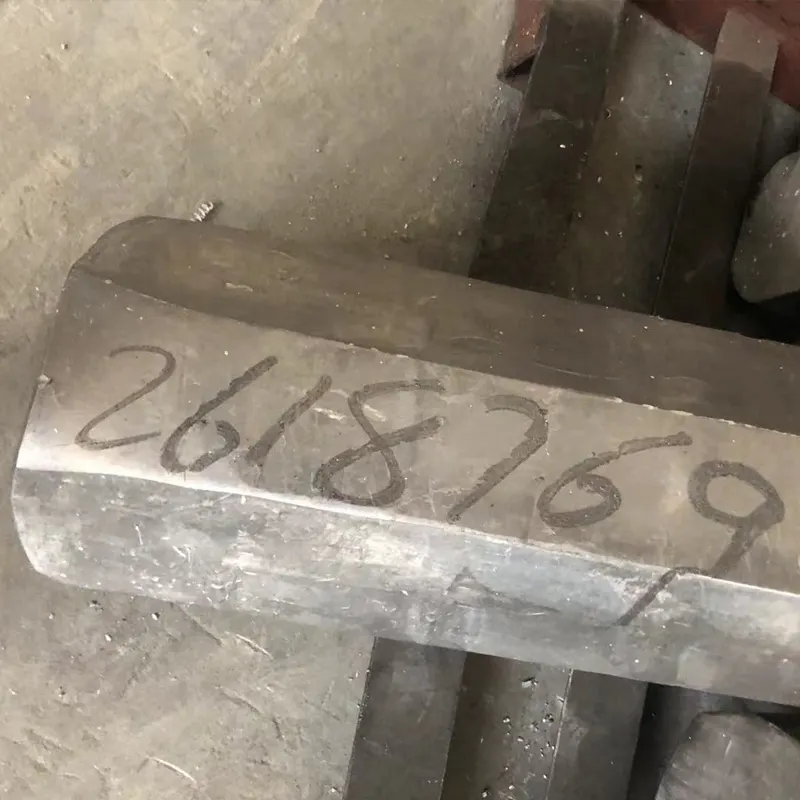

Product details of the aluminum alloy forgings

Product Overview

The production of SLAM aluminum alloy forgings adopts lean production model. The product will be strictly tested by our experienced inspectors before shipment to ensure it meets your demand for quality. This product is reliable in property and reputably appraised by customers in the industry.

Product Introduction

The specific details of aluminum alloy forgings are presented below.

Characteristics

The 6061 aluminum alloy forged rod has several characteristics that make it a top choice for various applications, including:

1. Excellent strength-to-weight ratio: This alloy has excellent strength-to-weight ratio, making it perfect for applications that require lightweight materials.

2. High corrosion resistance: It has excellent corrosion resistance, making it an ideal choice for applications exposed to harsh environments.

3. Superior machining ability: 6061 aluminum alloy forged rod is easy to machine, enabling it to be made into various complex shapes and structures.

4. Great weldability: This alloy has great weldability and can be easily joined using various welding techniques, such as TIG, MIG, and stick welding.

Chemical Composition

The chemical composition of 6061 aluminum alloy forged rod is as follows:

Silicon (Si): 0.4 – 0.8%

Iron (Fe): 0.7%

Copper (Cu): 0.15 – 0.4%

Manganese (Mn): 0.15%

Magnesium (Mg): 0.8 – 1.2%

Chromium (Cr): 0.04 – 0.35%

Zinc (Zn): 0.25%

Titanium (Ti): 0.15%

Other elements: 0.15% each, maximum

Mechanical Properties

The mechanical properties of 6061 aluminum alloy forged rod are impressive, making it an excellent choice for various applications. Some of its mechanical properties include:

Tensile strength: 310 MPa (45 ksi)

Yield strength: 276 MPa (40 ksi)

Density: 2.7 g/cm3

Applications

The 6061 aluminum alloy forged rod has numerous applications, including:

1. Aerospace: It is used in the construction of aircraft structures, engine components, and space shuttles.

2. Automotive: It is used in the manufacturing of automobile parts, such as wheels, suspension parts, and crash structures.

3. Marine: It is used for marine components and structures because of its high corrosion resistance.

4. Sports equipment: It is used in the manufacturing of sports equipment, such as bike frames, golf clubs, and tennis rackets.

Conclusion

The 6061 aluminum alloy forged rod is an excellent option for applications that require high strength, good corrosion resistance, and easy machinability. The alloy possesses several characteristics and mechanical properties that make it a popular choice for various industries, including aerospace, automotive, marine, and sports equipment. As a result, the 6061 aluminum alloy forged rod is a value-for-money investment, making it an ideal choice for those seeking quality materials with multiple applications.

Company Information

Shanghai Lockheed Aviation Materials Co., Ltd. is mainly engaged in the production and sales of SLAM insists on combining standardized services with personalized services to meet customers' different needs. This contributes to the brand image building of our company's quality service. Do not hesitate to contact us if you are interested in our