SLAM-Professional 20+ years aluminum manufacturer with high quality and good price.

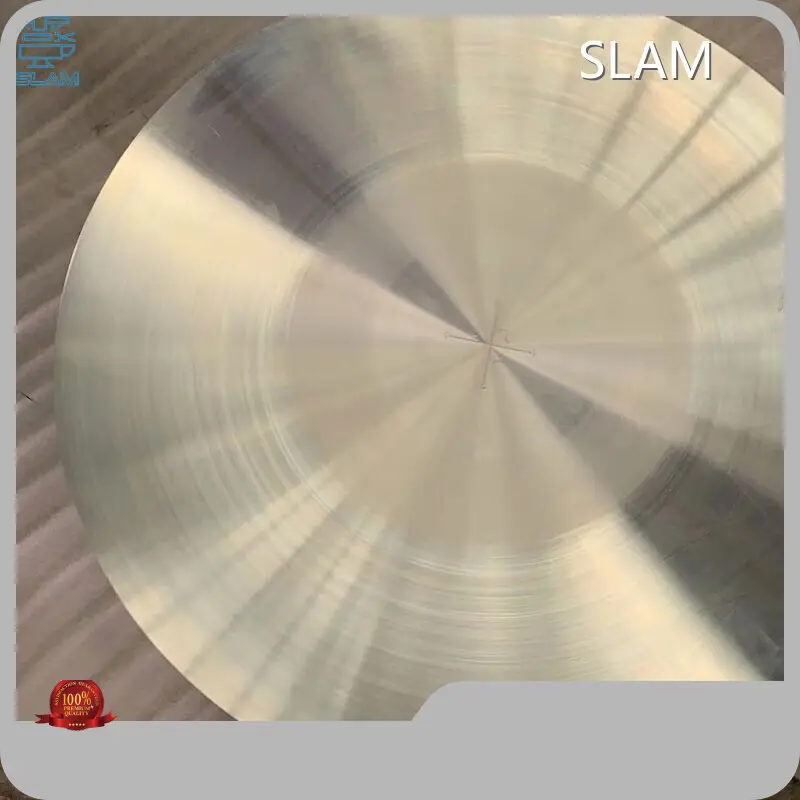

SLAM Forge Alloy Highly Rated for Manufacturing Industry

Product details of the forge alloy

Quick Detail

All raw materials used to manufactured SLAM forge alloy have to go through stringent quality checking procedure. It is developed with the best functionality and quality. The forge alloy produced by SLAM can be used in many fields. Shanghai Lockheed Aviation Materials Co., Ltd. can arrange free samples of forge alloy for quality testing with our pay for freight.

Product Description

Compared with similar products, our company's forge alloy has the following outstanding features.

Characteristics

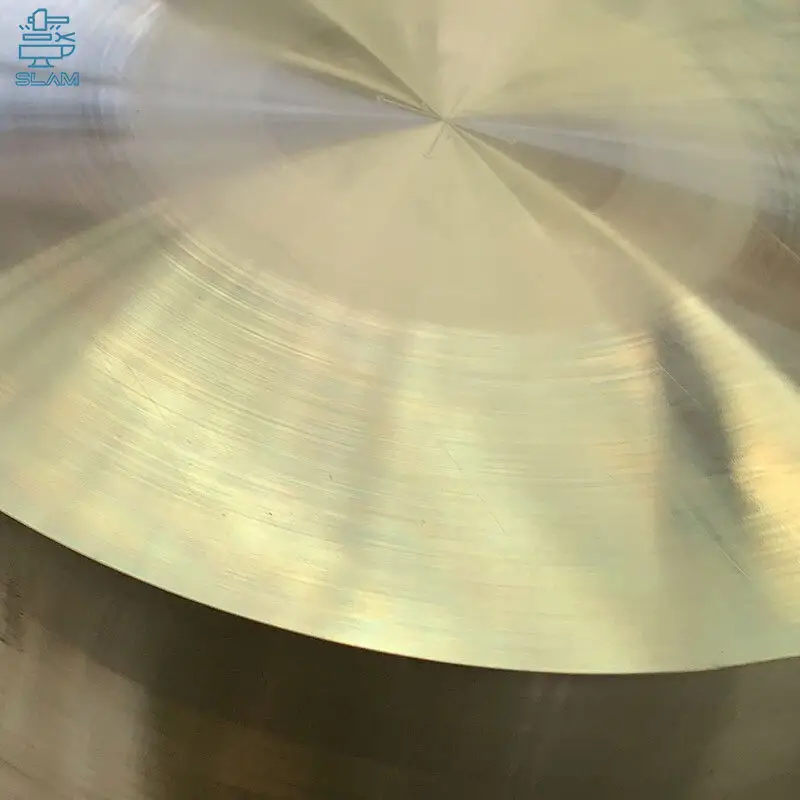

1. High Strength: 7A04 aluminum forging round disc has excellent mechanical properties, with a high tensile strength and yield strength.

2. Good Corrosion Resistance: The material can resist corrosion from seawater, air, and alkali, which makes it suitable for marine engineering and other fields that require high corrosion resistance.

3. Excellent Processing Performance: The material can be forged, extruded and rolled, with good processing performance, and can be produced into a variety of shapes and specifications.

4. Low density: The density of 7A04 aluminum forging round disc is 2.77 g/cm³, which is only one-third of the density of steel, which can reduce the weight of the structure.

5. High Temperature Resistance: 7A04 aluminum forging round disc has good high-temperature resistance, which can maintain good mechanical properties at high temperatures.

Chemical Composition

7A04 aluminum forging round disc is mainly composed of aluminum, magnesium, zinc, and copper. The specific chemical composition is shown in the table below:

Chemical Composition (%) Min Max

Aluminum (Al) 93.5 -

Magnesium (Mg) 1.8 2.8

Zinc (Zn) 5.0 6.5

Copper (Cu) 0.20 0.40

Iron (Fe) - 0.50

Manganese (Mn) - 0.50

Silicon (Si) - 0.40

Mechanical Properties

The mechanical properties of 7A04 aluminum forging round disc are excellent, with high strength, good toughness, and excellent corrosion resistance.

Tensile Strength (MPa) ≥550

Yield Strength (MPa) ≥485

Elongation (%) ≥10

Hardness (HB) ≥190

Fatigue Strength (MPa) ≥140

Applications

1. Aerospace Industry: 7A04 aluminum forging round disc is mainly used in aviation and aerospace industries, such as aircraft structural parts, helicopter rotors, and spacecraft structural parts.

2. Marine Engineering: The material has excellent corrosion resistance, which is suitable for marine engineering, such as marine hulls and other structural parts.

3. Transportation: The material is used in the transportation industry, such as high-speed trains, subway trains, and automotive structural parts.

4. Sports Equipment: 7A04 aluminum forging round disc is used in sports equipment such as bicycles, racing cars, and golf clubs, due to its high strength, light weight, and good processing

performance.

Conclusion

In conclusion, 7A04 aluminum forging round disc is an excellent high-strength aluminum alloy with good mechanical properties, excellent corrosion resistance, and good processing performance. It is widely used in aviation, marine engineering, transportation, and sports equipment industries, due to its unique properties. With the development of technology, 7A04 aluminum forging round disc will surely play an increasingly important role in various fields.

Company Introduction

Situated in Shanghai Lockheed Aviation Materials Co., Ltd. is a comprehensive company. We are mainly dedicated to the business of SLAM always gives priority to development. We continuously develop our main business and keep pursuing quality excellence, so as to attract more customers with sincerity and dedicated services. Our company has introduced an advanced management model and built a strong and professional elite team. They pave the way for our better development. In the early stage, we conduct a communication survey to gain an in-depth understanding of the customer's problems. Therefore, we can develop solutions that best suit the customers based on the results of the communication survey.

If you have needs for purchasing our products in bulk, please contact our official customer service personnel.